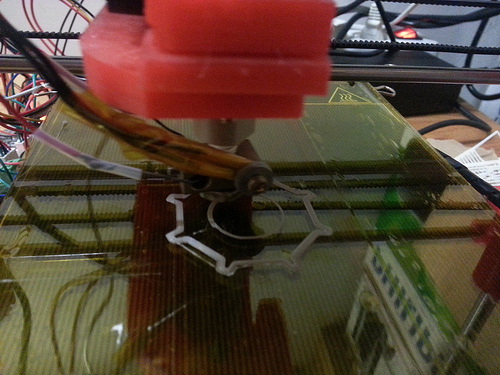

To improve the quality of my prints I ordered a glass sheet for the heated print bed. The glass sheet has the dimensions of 180x140x3 mm. I wrapped one site of the glass plate in kapton tape.

The kapton tape has the advantage that extruded plastic adheres easily and the cooled parts can be peeled off without damaging it. I tried to apply the tape without any bubbles.

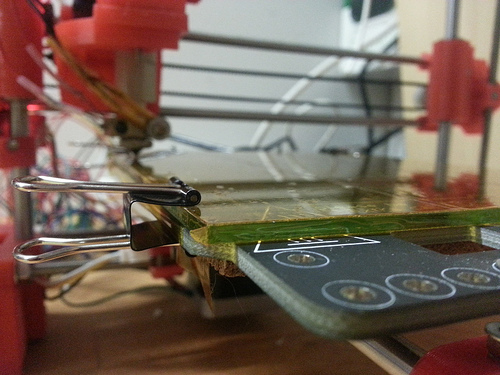

When I first started calibrating the z-axis of my printer a couple of month ago I had some accidents where the hot noozle(185°C) has damaged the heated bed. The glass sheet now protects the heated bed against further damages. But the main reason for the glass sheet is that it provides a plane surface and it does not bend while my heated bed is slightly bowed. Normal glass should not be used for temperatures over 80-100°C but this is not a problem here because when using PLA a temperature of 60°C is enough. The glass sheet is kept in place with four binder clips each attached to the heated bed.

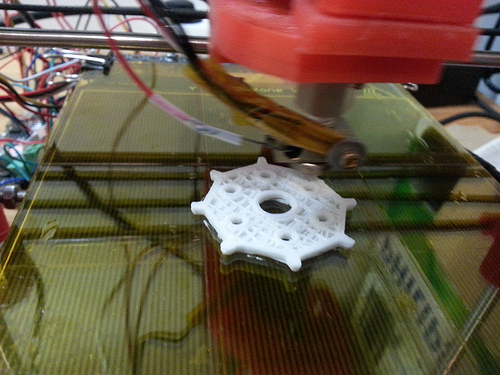

The printed results are looking good. Adding a glass sheet to the printer has been a real and very cheap improvement.

WRITTEN BY

Sebastian Glahn is a Senior Software Engineer living in Cologne. He writes about Software Development, 3D-Printing, Robots and other stuff. He is also a maintainer of several open source projects.