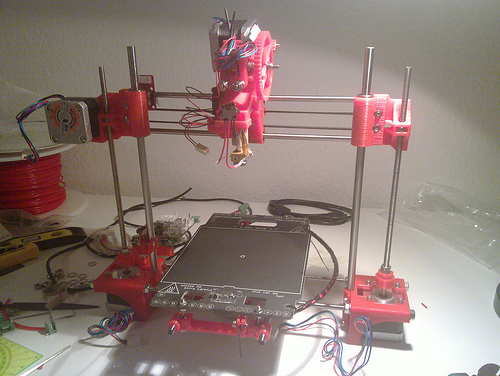

(Click here for Part two). I received my unassembled Portabee 3d printer kit. The Portabee is not only the world´s first portable 3d printer it is also affordable. I want to share my experiences. The Portabee is based on the RepRap Wallace and uses 3 mm PLA filament and a 0.5 mm extruder nozzle. The build volume is 120x120x120 mm. With an 365 Euro price tag unassembled the Portabee is really cheap. But you should keep in mind the shipping costs of ~75 Euro plus ~90 Euro Import VAT (Einfuhrumsatzsteuer) at least here in Germany. That makes a total of ~530 Euro. The lead time was about 4 weeks, shipping took 3 days.

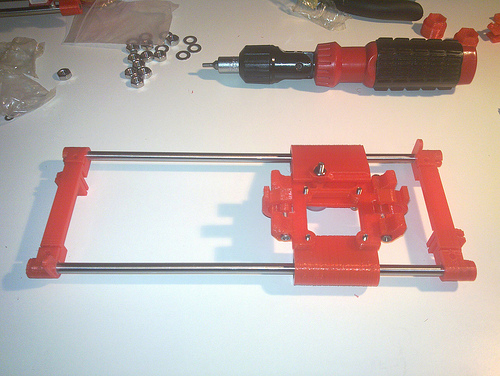

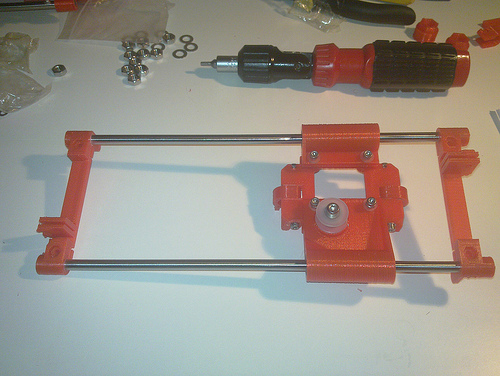

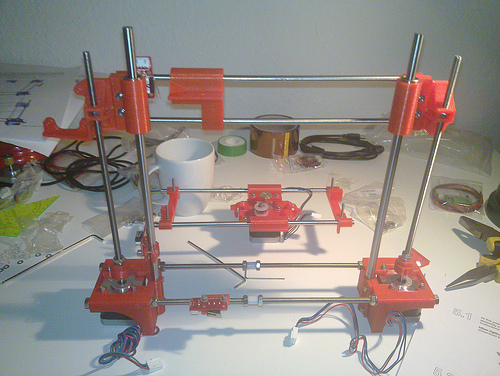

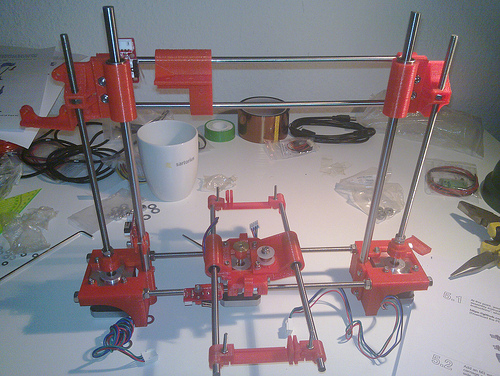

Here is what you will find in the box: The printed parts (red), 1kg 3mm PLA filament (red), the motors (two z motors, an x motor, an y motor and the extruder motor), the printbed, a lot of nuts, washers, bearings, bolts, screws, rods, the electronics a modified Gen6 board and the endstops). Also provided is a spirit level, 3 wrenches, Kapton tape a pack of instant coffee and more.

The quality of the printed parts that come with the Portabee is very good. The step by step assembly instructions (One for the printer and one for the extruder) are very detailed but outdatet at several places. The bare-bones case design of the printer is very minimalistic (but in a good way) and pragmatic.

A problem occured with the endstops. They came not as they should because they are soldered the other way around. After a small adaption (basically a rotation) they are working.

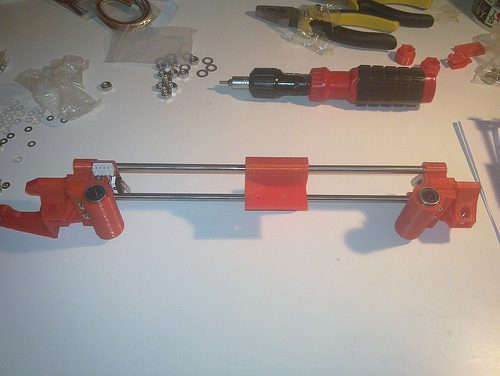

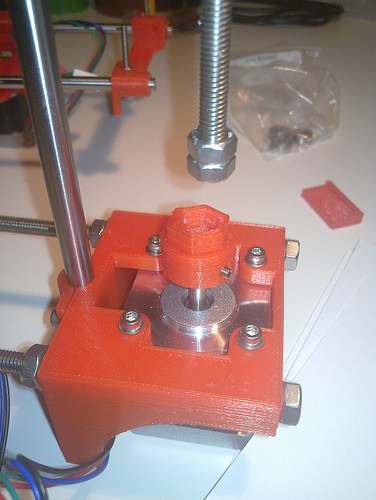

In my kit one z shaft coupling is a weak point. The coupling doesn´t hold the nut very good. Now the rod is pressed into the coupling basically by the weight of the x axis and the extruder. I´m not sure how bad that affects the printing process.

This z shaft coupling is a weak point

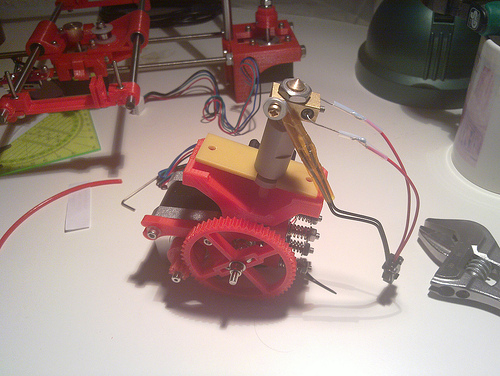

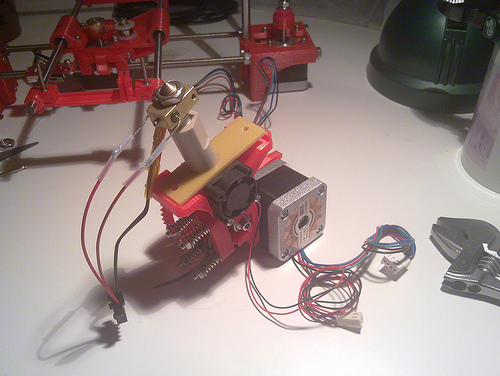

The extruder and the heatbed involves some soldering. The Portabee uses a Wade Extruder Version 3 which is a complex and heavy thing.

In the process of wiring I found out that I hadn´t checked the length of the motor cables which is different so I had to unscrew the motors and switch them. To be continued…

WRITTEN BY

Sebastian Glahn is a Senior Software Engineer living in Cologne. He writes about Software Development, 3D-Printing, Robots and other stuff. He is also a maintainer of several open source projects.